In the first post of “Tensile behaviour of UHPC” (click here to see it) we defined the uniaxial tensile behaviour of plain concrete using both a stress-strain relationship up to maximum load and a stress-crack opening relationship from this point onwards up to a maximum crack width. We explained that one of the main consequences of the ability of concrete to transfer a “stitched force” between the two planes of a crack according to the distance between them (crack opening) is the fact that strength depends on specimen size, what is commonly called scale-effect. It could have been a minor issue for science if not for the fact that linear elastic theory couldn’t predict that. In this post we are going to explain (i) the concept of equivalent flexural strength; (ii) the nature of the scale-effect phenomenom, (iii) the way we can easily consider the scale-effect by correcting softening stress-strain behaviour according to structure depth and (iv) some notions about brittleness.

Warning 1: We strongly recommend to read post (I) before digging into this one !! (click here)

Warning 2: It may be kind of tedious to read if you don’t have basic knowledge on concrete design !!

Let’s get started !!

FLEXURAL STRENGTH

One of the main problems that linear elastic beam theory had to face was the fact that experimental tests showed that flexural strength of concrete varies according to specimen depth when it was supposed to keep constant. We should not confuse bending moment capacity with flexural strength. So, what is flexural strength?

According to the way we obtain flexural strength, we can give following general definition:

Flexural strength is the maximum bending moment (M) to elastic modulus of the section (Wel) ratio

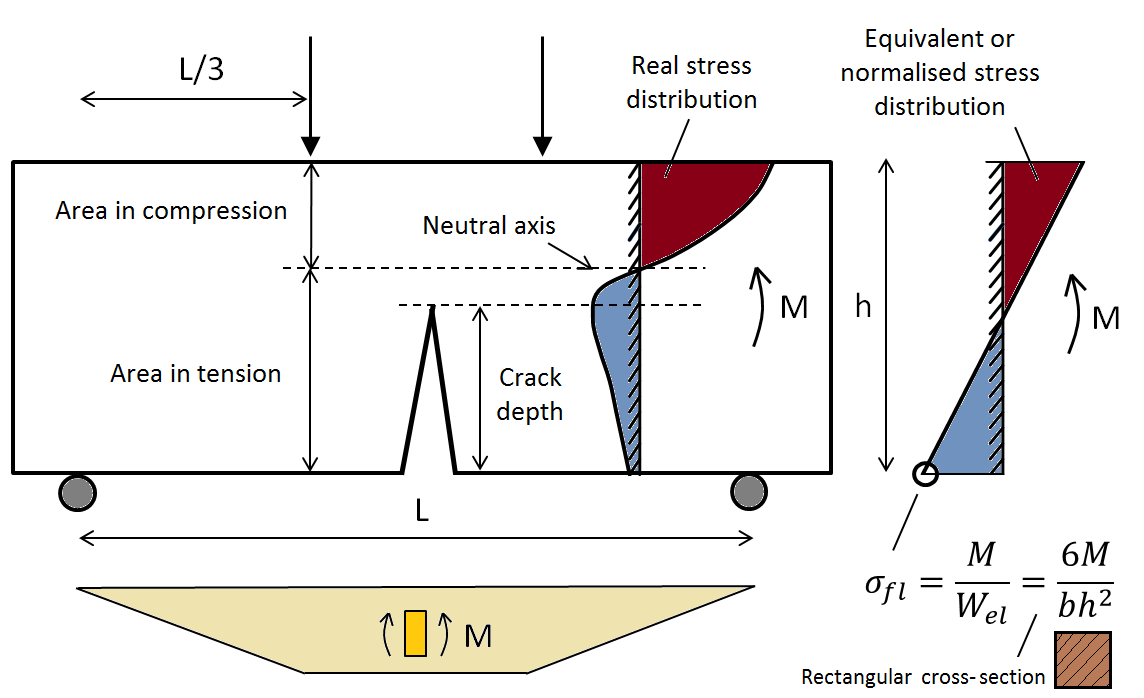

However, if we want to understand the physical meaning, next figure can be helpful. On it, we have represented a four point bending test carried out on a square cross-section specimen with depth (h) and span (L) at maximum load. It has also been represented an hypothecial stress distribution in the failure section. Red area represents the area under compression, while blue area represents the area under tension. As there are no axial forces, both areas are the same.

Note that a crack opening equal to zero corresponds to the initiation of softening once matrix tensile strength is reached. As this test is an statistically determined configuration, maximum bending moment (M) can be easily obtained according to load applied. Bending moment distribution has also been represented in yellow. Obviously, bending moment obtained from the integration of the real stress distribution must coincide with that.

So, for a given maximum bending moment, and whatever the real stress distribution is, the flexural strength represents the maximum stress in both compression and tension of a linear elastic distribution of stresses in the failure section that gives maximum bending moment. In other words, flexural strength is the answer to the following question:

What would have been the maximum tensile stress reached at maximum bending moment if the material had behaved as a linear elastic one? – Flexural strength

Why is this parameter so important? Cause if there were no scale-effect in concrete, flexural strength would be the same regardless the specimen depth. That is why flexural strength is used to study scale-effect in concrete.

SCALE-EFFECT

Once we know this concept, following step is to make a numerical analysis of the flexural strength versus normalised displacement of a specific concrete in a bending test using different depth values. We have introduced the normalised displacement parameter defined as the ratio between any displacment obtained and the linear elastic displacement reached when the maximum tensile stress achieved in the cross section is equal to tensile strength of the matrix. Just to obtain a more meaningful picture 🙂

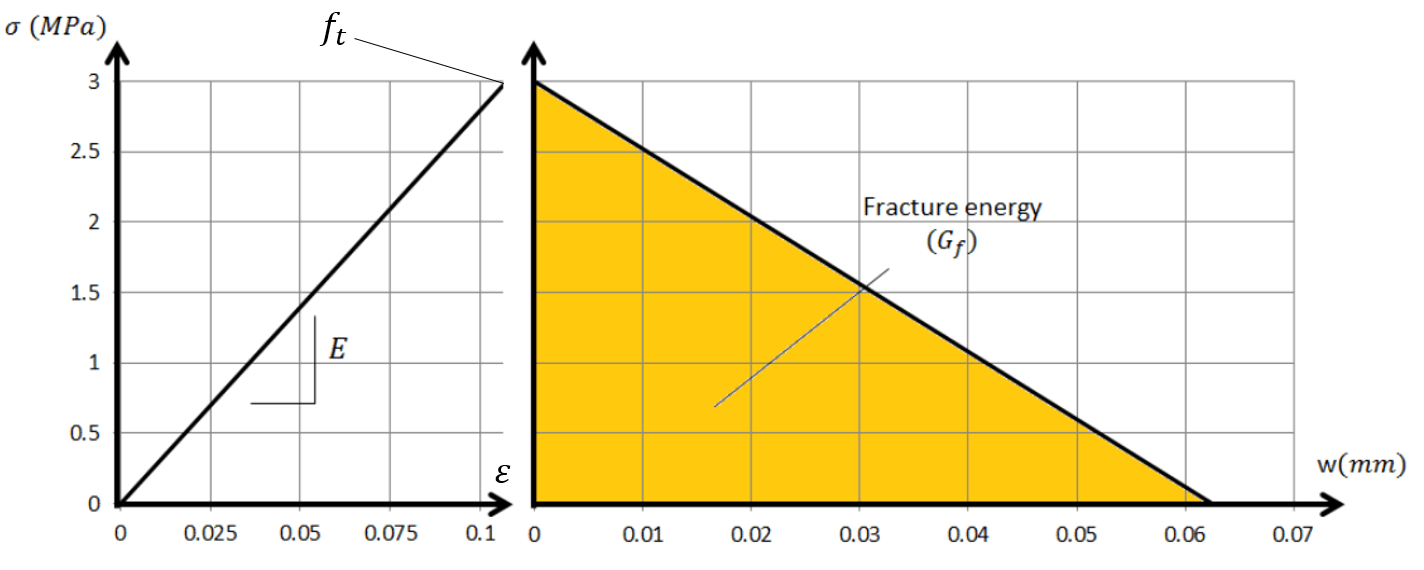

Constitutive tensile behaviour used corresponds to a C30. For simplification, a linear elastic stress-strain behaviour up to matrix cracking strength (ft) have been used and also a linear stress-crack opening relationship. Crack opening at zero stress considered was 0.625 mm according to Model Code 2012. Constitutive behaviour used is shown in the following picture. Area under the stress – crack opening relationship is called fracture energy.

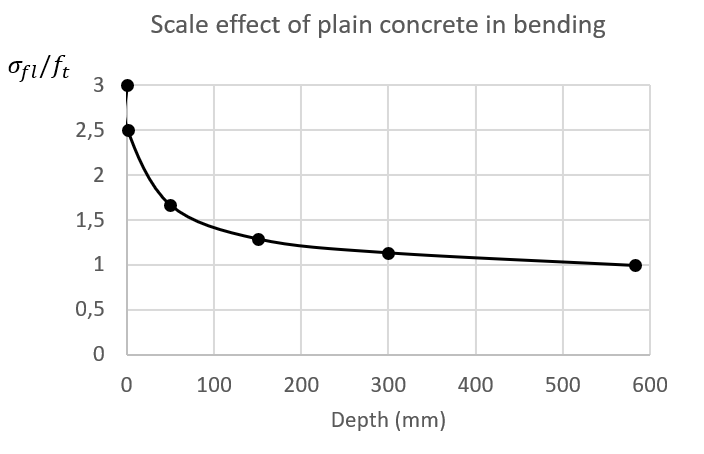

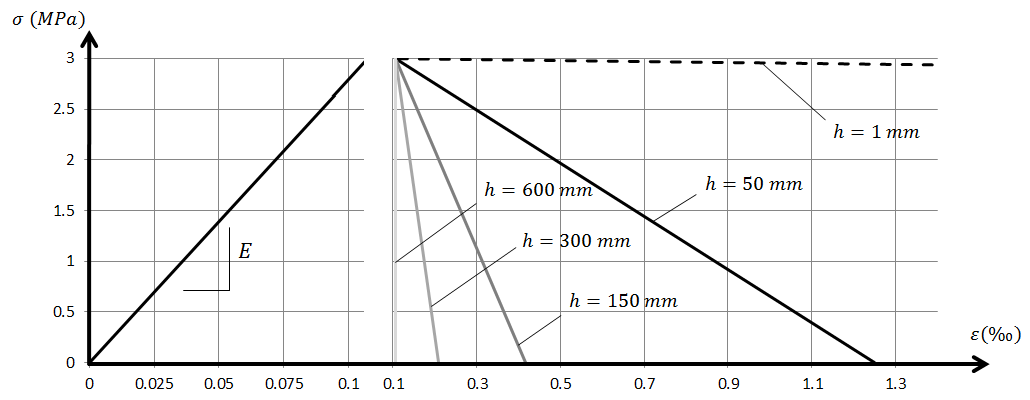

We run the numerical model for 5 different beam depths: (i) 1 mm; (ii) 50 mm; (iii) 150 mm; (iv) 300 mm; (v) 600 mm. We are aware that using a 1 mm depth specimen has no physical meaning, but it can give some interesting information. Following curve represents the flexural strength to matrix cracking strength (ft) versus normalised displacement for the last four beam depths.

As it can be clearly seen, we can draw some conclusions:

(i) Flexural strength to matrix cracking strength (ft) is higher the smaller the specimen depth

(ii) Normalised displacement at maximum load is higher the smaller the specimen depth

(iii) Kind of deflection-hardening behaviour is expected even in a softening material when specimen depth is small enough

So at this very point, one could make following question: how is that flexural strength is higher than matrix cracking strength? Wasn’t plain concrete suppose to be a britlle material in which once cracking strength is reached suddenly breaks? The answer to that question can be summarised in the following sentence.

Plain concrete is not a brittle material but a quasi-britlle one which is able to transfer a “stitched stress” between the two planes of the crack once a crack appears

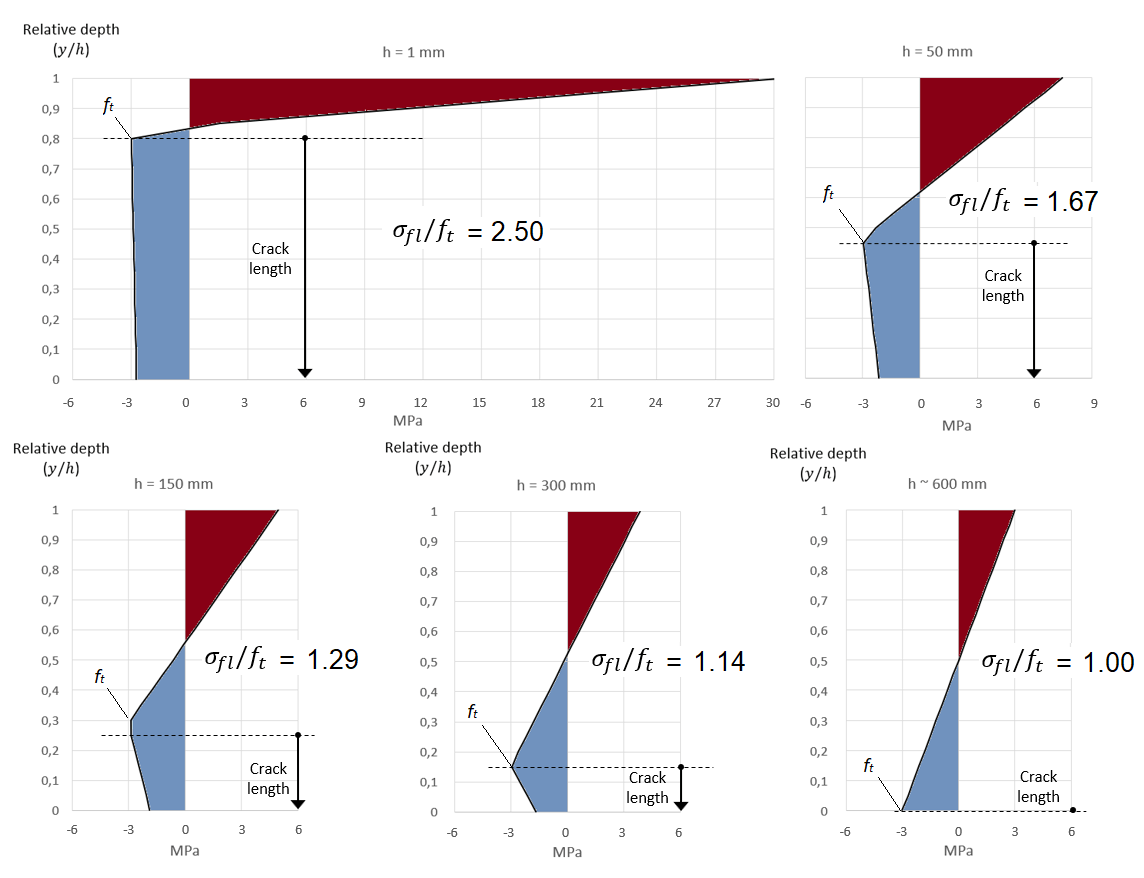

Why could that sentence explain the scale-effect? To answer that we have made following figure. On it we have represented the stress distribution at maximum bending moment along the specimen depth. Take a look at it.

After seeing this picture, we can notice that:

(i) Stress distribution at maximum load varies according to specimen depth

(ii) Maximum bending strength is achieved when concrete is already cracked as it is able to transfer stress between the two crack planes. That is what justifies scale-effect phenomenon

(iii) As specimen depth decreases, softening behaviour has more relevance in the maximum bending moment; neutral axis moves up to balance axis forces; and curvature increases leading to high rotational capacity and ductililty

(iv) Crack opening observed at maximum load increases as specimen depth also increases, but crack length decreases

Looking at the two previous figures we can make the two following appreciations:

(i) As specimen depth increases, concrete becomes more brittle and flexural strength gets closer to matrix cracking strength (or tensile strength). At a certain specimen depth, structure becomes perfectly brittle and flexural strength matches matrix cracking strength. According to that model, there is a lower limit of flexural strength when depth increases which is matrix cracking strength. What happens above this depth may find a more suitable explanation in linear elastics fracture mechanics.

(ii) As specimen depth decreases, concrete behaves more and more similar to a perfectly plastic material, increasing its rotation capacity and its ductility. According to that, there is also an upper limit for flexural strength when specimen depth tends to zero (assuming that an infinite compressive strength and curvature are physically possible), which is three times the matrix cracking strength, according to plasticity theory. These two lower and upper limits can be seen in following picture.

Flexural strength in quasi-brittle materials, such as concrete, varies from 1 to 3 times tensile strength according to specimen depth and fracture energy of concrete.

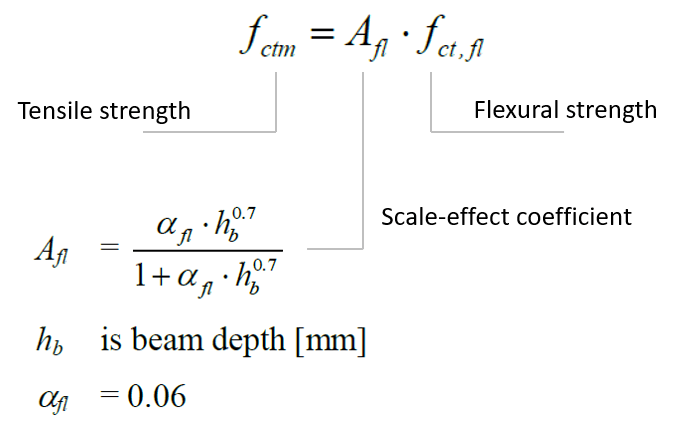

Knowing that, it is now easy to understand the formulation proposed by Model Code 2012 to obtain the flexural strength according to tensile strength and specimen depth. Now, we know the reasons for that equation. But don’t forget one thing: concrete is already cracked once flexural strength is reached !!

STRESS-STRAIN RELATIONSHIP FOR SECTIONAL ANALYSIS

Engineers are commonly used to carrying out sectional analysis calculations using stress-strain constitutive relationships. However, constitutive relationship of the C30 used is based on a stress-crack opening behavoiur. Could be turn the softening stress-crack opening behavoiur into a stress-strain one? Yes, it could. But guess what, this transformation has to be done according to the structure depth !!

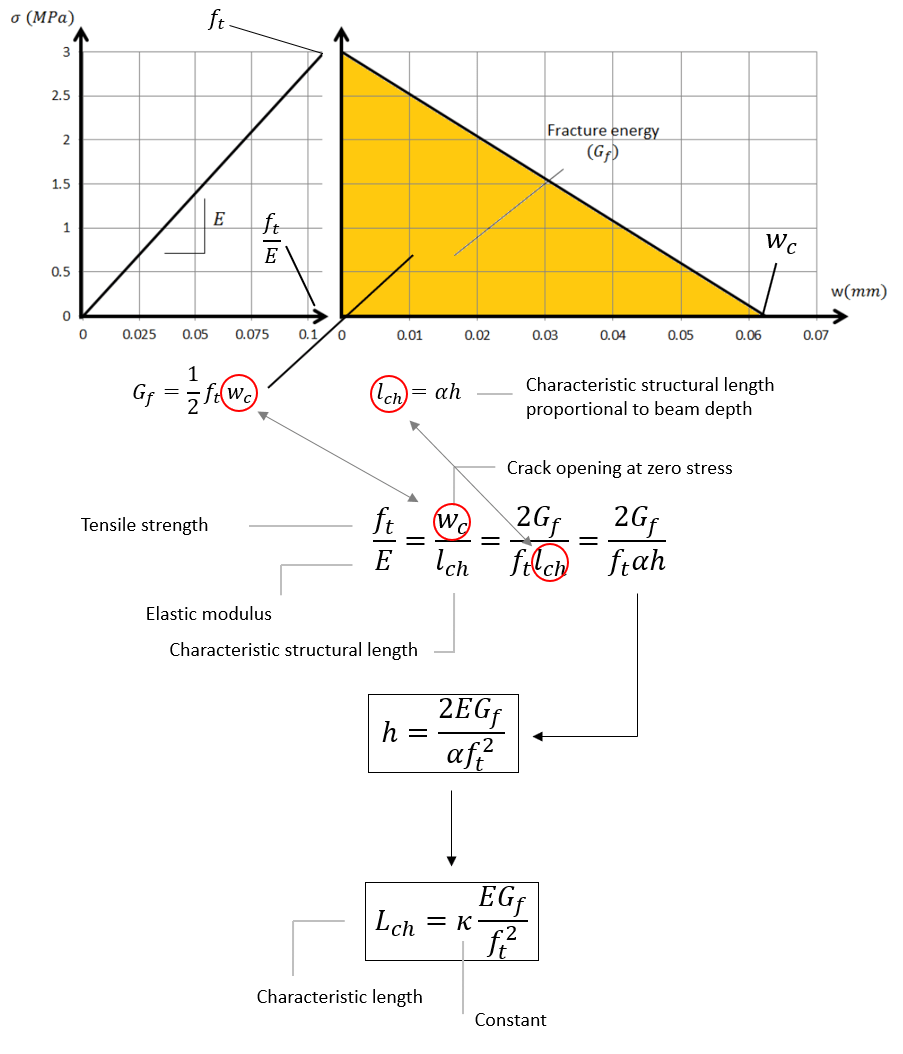

The most common way to turn the stress-crack opening relationship into stress-strain one is to divide the former one by a length parameter which is proportional to the beam depth. This length parameter is commonly called the “characteristic structural length”.

In the following picture, the characteristic structural length used was directly the beam depth. Using this transformation and the constitutive stress-crack opening relationship, we can obtain the following softening stress-strain relationships for different beam depths. Note that a different softening stress-strain relationship is obtained for each beam depth !!

Stress-strain relationship is never a constitutive property once concrete is cracked

BRITTLENESS

It is important to distinguish between “characteristic structural length”, which may be defined as the length parameter we should use to turn the stress-crack opening realtionship into stress-strain one, and “characteristic length”, which according to fracture mechanics theory is a material property.

Look at the previous figure. There is a certain depth in which softening behaviour is vertical, leading to a perfectly brittle behaviour. The depth from which concrete behaves as a pure brittle material is called “characteristic length” and is a material property. You can follow the process to obtain it in the following picture !!

This is the so-called “characteristic length” which tell us that in quasi-brittle materials, degree of brittleness depends on fracture energy and tensile strength. As tensile strength in concrete increases as compressive strength does, high compressive strength concretes are more britlle that low compressive strength ones for a given beam depth. This is something we all know, but here is the explanation !!

So, how could be improved brittleness (same thing as increasing characteristic length) when dealing with ultra-high compressive strength concretes? Using fibres !! Fibres provide larger fracture energy !! That is why the use of fibres is mandatory in UHPC, to ensure a minimum ductility requirement !!

If the size of your structure is higher than the characteristic length of the material, be careful cause tensile strength can be even lower !! But don’t worry, the size of most common concrete structures is lower than characteristic length of concrete, and when concrete is combined with steel reinforcement this effect can be neglected. It only affects to plain concrete !! Therefore, in case of reinforced concrete we can neglect tensile contribution of concrete !! 😉 This is something we already knew. However, it has a huge influence in case of fibre-reinforced concrete.

Even though this post may be quite tedioius to read, these notions are important to define and understand UHPC tensile behaviour. What is the tensile behaviour of UHPC? Is it different from plain concrete? Too much? These question will be answered in the next post of “Learning UHPC” section. Don’t miss it !!

One Response

Great post to understand better a rather complex phenomenon in concrete.

Comments are closed.