H2020 project SMARTINCS (2019-2024)

Background: This project is implementing new life-cycle thinking and durability-based approaches to the concept and design of concrete structures, using self-healing concrete, repair mortars and grouts together with key enabling technologies. Part of the research is carried out integrating these technologies in UHPC. The potential of this project is to create a breakthrough in the […]

EMFF project OpenMode (2019-2021)

Background: There are several types of mussel farming systems, of which the most common are the longine (extensive), and the raft (intensive). The last has been traditionally used in Spain due to the high concentration of phytoplankton in the water and the availability of eucalyptus wood. As since 2018 Formex® beams are an option, RDC […]

H2020 project SELMUS (2016-2017)

Background: After the patent of the UHPC rafts in 2015, RDC required to build full-scale pilots of these floating structures to prove to the farmers their durability and suitability. This shaping strategy also required a wide communication and dissemination campaign to familiarize the sector with this new technology. Being RDC a small company and with […]

Design of the first UHPC bridge in Spain, located in Beniarjó (Valencia)

Background: RDC designed in 2018 the first UHPC road bridge built in Spain. The solution was required to rebuild a bridge over the Vernissa river, which was destroyed by the floods on year 2007. The bridge consisted of a bidirectional decks supported existing piles to save six spans, each of them of 10 m. The […]

Reparation of a bridge in Alcira with UHPC beams

Background: In 2019, a concrete bridge in Alcira (Valencia) suffered the impact of a truck, which destroyed its two first “double-T” beams. The contractor requested to RDC the design of the new two beams with UHPC, so if in the future there is a new impact of a truck against them they do not suffer […]

UHPC flooring for a terrace in a recycling plant in Guadassuar (Valencia)

Background: UHPC performance allows to design large format thin slabs, reducing the installation time and the number of joints in the area covered. In 2017, RDC designed with UHPC the slabs of the largest terrace of the recycling plant Ribera del Xuquer (Guadassuar, Valencia). In this case, texture and color were selected to achieve metallic […]

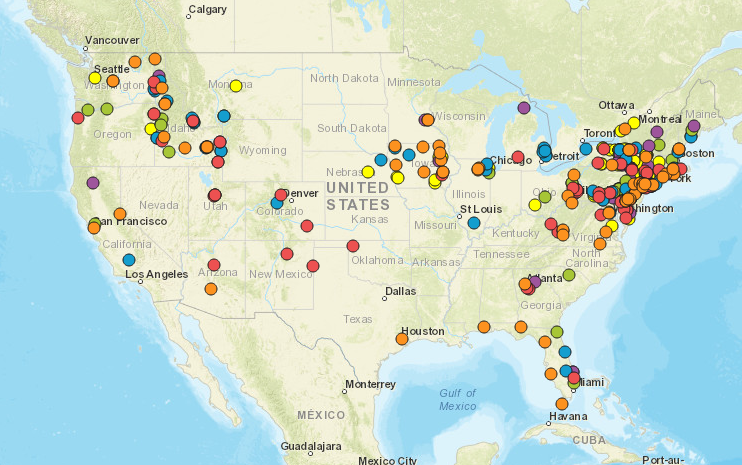

THE USE OF UHPC IN BRIDGES IN THE UNITED STATES OF AMERICA

Good morning, everyone! Today I would like to speak about the progress in the use of UHPC in the US, focused mainly in the most dynamic application in the last decade: The use in bridges to increase their durability and minimize their maintenance costs. This type of application was generalized previously in Switzerland with the […]

Design of floating UHPC structure for the substation of a 5 MW floating PV plant in Alqueva (Portugal)

RDC has designed the floating structure to host the substation of a 5 MW floating PV plant located in Alqueva (Portugal). This dam is the largest in the EU, and the installation is the largest in a EU dam.

Offshore UHPC farms after 6 years

It feels like it was yesterday when the entire RDC team went to Vasc Country to install our first raft, the first floating UHPC farm in the world. It was October of 2016. Now, 6 years later, is already a good moment to start checking if this solution is as good as we promised under the dynamic and aggressive marine environment.

Traditional rafts are 20 x 27 m floating structures typically made of eucalyptus wood and six steel floaters protected with GFRP. These structures are flexible and economic, but their lifespan does not generally exceed the 15 years, and their maintenance costs are significant. This problem was noticed by RDC, which designed and patented a UHPC raft in 2015.

Dramatic steel costs..

Good afternoon everyone! Welcome again to the UHPC for People Blog! As you may have noticed in your pockets, some of the latest international events, such as the Ukranian war, the energy crisis or the significant inflation in the Eurozone, have generated an increase of prices, which is quite significant in certain foods, raw materials […]